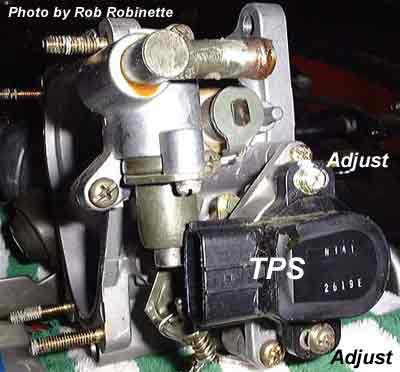

To adjust the TPS with a multimeter, first connect the positive lead of the multimeter to the TP terminal on the TPS and ground the negative lead of the multimeter. Next, rotate the TP screw clockwise until you see 0.6 volts on the multimeter. Finally, tighten the locknut and recheck the voltage.

- First, disconnect the negative battery terminal to avoid shocking yourself or damaging the vehicle

- Next, locate the TPS sensor on the throttle body and unplug it

- Using your multimeter, set it to read in Ohms mode and touch the leads to the two exposed wires on the TPS sensor

- The multimeter should register a reading of around 1-2 kilohms

- If the reading is not within that range, you will need to adjust the TPS until it is within that range

- To do so, loosen the screws holding the TPS in place and rotate it slightly until you get a reading within that range

- Once you have done so, retighten the screws and reconnect the negative battery terminal before starting up your vehicle to test it out

Credit: robrobinette.com

How Do You Calibrate a Throttle Position Sensor With a Multimeter?

How to Calibrate a Throttle Position Sensor With a Multimeter

A throttle position sensor (TPS) is a device that measures the position of the throttle in an internal combustion engine. The TPS is used to monitor and control the engine’s throttle.

In order to ensure that the TPS is functioning properly, it must be calibrated on a regular basis. This can be done with a multimeter.

To calibrate the TPS, follow these steps:

1. Connect the positive lead of the multimeter to the “+” terminal on the TPS. Connect the negative lead of the multimeter to ground.

2. Turn on the ignition but do not start the engine.

3. Set the multimeter to read DC volts in its 20-volt range.

4. Slowly open and close the throttle until you findthe voltage reading onthe multimeter changes from 4 volts or lessto 12voltsor morewithinthe specified range for your vehicle’s makeand model year(this will be given in your vehicle’s repair manual). 5 Note this voltage reading as your “throttle closed” calibration point (Cp).

6 Keep track of how many degrees you rotatedthe throttlestopscrewto reach this point soyou can return itto this exactposition later if necessary . 7 Open and close throttle again until you findthe voltagethe meterreads changesfrom 12 voltsor moreto 4voltsor lesswithinits specified range; note this second voltage as your “throttle open” calibration point (Co). 8 Again, keep track of how many degrees you rotatedthe stop screwsoyou can return itexactlyto this position later if necessary .

9 Compare your Cp and Co readings against those givenin yourvehicle’srepairmanual; they should match or be within 1 voltof each otherfor proper calibration . If they are not within spec,then loosenbutdountightenthe screwsuntiltheyare bothreadingwithinspecificationson themultimeter attheir respective positions(closedandopen), making surenot tomove bothscrewsat once oryou will have tomoveonebackagain totry togetbothinto their correctpositions! 10 Once bothscrewsaretighteneddown securely , recheckyour readings one lasttimebeforestartingengineand drivingaway .

How Do I Adjust My Tps Voltage?

Assuming you would like a blog post discussing how to adjust the throttle position sensor (TPS) voltage:

The TPS is a potentiometer that is used to measure the angle of the throttle blade. The output voltage from the TPS increases as the throttle is opened.

The PCM uses this information, along with input from other sensors, to determine how much fuel to inject and when to ignite the spark plugs.

There are two screws on the back of the TPS that can be used to adjust the sensor. One screw adjusts the idle position and the other adjuststhe full throttle position.

To adjust either screw, loosen it slightly and then turn it clockwise or counterclockwise until you hear a click. Do not over-tighten these screws; doing so may damage them. After making an adjustment, always check for proper operation of all systems before driving your vehicle.

How Do You Calibrate a Throttle Position Sensor?

A throttle position sensor is a small electronic device that measures the angle of the throttle valve in an internal combustion engine. The purpose of the sensor is to help the engine control computer (ECC) determine how much air is entering the engine so that it can adjust the fuel injection and ignition timing accordingly.

There are two types of throttle position sensors: linear and rotary.

Linear type sensors measure the relative position of the throttle plate, while rotary type sensors measure the absolute angle of the throttle shaft.

Most modern vehicles use a Throttle Position Sensor (TPS) to monitor throttling activity. The TPS provides input to the vehicle’s computer, or Engine Control Unit (ECU), which uses this data to calculate air density and adjust fuel injector pulse width accordingly.

This ensures optimal mixture throughout different operating conditions and prevents premature spark knock or “pinging” during high load operation.

To calibrate a TPS, you will need either a digital multimeter or an oscilloscope. If using a multimeter, connect it to TP1 and TP2 on your TPS connector.

With your key in the ON position but not running, slowly turn your throttle from 0% to 100%. You should see around .45 volts at 0% and 4.5 volts at 100%. If your readings are outside those ranges, your TPS needs adjusting.

If using an oscilloscope, connect one lead to TP1 on your TPS connector and ground the other lead on any metal part of your car chassis. With your key in ON position but not running, slowly turn your throttle from 0% all they way open until it stops moving—this should take about 2 seconds total.

How Many Volts Should a Tps Have?

A throttle position sensor (TPS) is a sensor used to monitor the position of the throttle in an internal combustion engine. The TPS is located on the throttle body and is connected to the throttle shaft. The TPS monitors the position of the throttle and sends a signal to the engine control unit (ECU).

The ECU uses this information to regulate the air/fuel mixture and ignition timing.

The TPS should have a voltage of 0.5-4.5 volts.

How to Calibrate Throttle Position Sensor Using a Multimeter (Set TPS)

How to Calibrate Throttle Position Sensor

A throttle position sensor is a vital component in modern vehicles. It helps the engine control module (ECM) to determine how much fuel to inject into the cylinders by monitoring the position of the throttle plate. If the TPS is not functioning correctly, it can cause all sorts of drivability issues such as poor fuel economy, engine misfires, and stalling.

Luckily, calibrating a TPS is a relatively easy process that can be done at home with just a few tools. In this article, we’ll show you how to do it step-by-step.

Before you begin, make sure that the vehicle is parked on level ground and that the battery has plenty of charge.

You’ll also need an OBD2 scanner or code reader and a small flathead screwdriver.

1) Locate the TPS on your vehicle. It’s typically mounted on the side of the throttle body or intake manifold.

On some older vehicles, it may be located on the carburetor instead.

2) Use your OBD2 scanner or code reader to check for any trouble codes related to the TPS. If there are any codes present, diagnose and repair them before proceeding with calibration.

3) With your small flathead screwdriver, turn the adjusting screws on the TPS until they’re loose enough to turn easily but not so loose that they fall out completely. Do not remove them entirely!

4) Connect your OBD2 scanner or code reader to the vehicle’s diagnostic port (usually under the dash).

With the ignition key in ON position but engine off, enter into “Throttle Position Sensor” mode using your scan tool’s menu buttons. The exact steps will vary depending on your specific model of scan tool – consult your user manual if you’re unsure how to do this..

Look at data being displayed by your scan tool while slowly turning one ofthe adjusting screws clockwise until reaching rich mixture condition(peak value around 100%). Now slowly turn back same adjusting screwcounterclockwise same number of turns as turned clockwise before(exactly!) until reaching lean mixture condition (peak value around 0%).Now peak value should be close to 50%. If not – repeat procedure from step 4 again until achieved desired result.

Conclusion

If your car is having issues with idling or starting up, it may be time to adjust the TPS. The TPS, or throttle position sensor, is what tells the computer how far the throttle is open. You can use a multimeter to check if the TPS needs to be adjusted.

First, locate the TPS on your engine. It will be attached to the throttle body. Once you have found it, disconnect the electrical connector.

Then, set your multimeter to ohms and touch each of the exposed wires with the probes.

The reading should be between 1k and 2k ohms when at rest. If it’s not within that range, you’ll need to adjust the TPS.

To do so, loosen the screws holding it in place and rotate it until you get a reading within that range. Then, tighten the screws back down and reconnect the electrical connector.