The oil dipstick may not go back in due to misalignment or debris obstructing the tube. Ensure the dipstick is straight and clean.

A common issue faced by vehicle owners is difficulty reinserting the oil dipstick. This minor yet frustrating problem can stem from several causes. Misalignment is a frequent culprit, where the dipstick isn’t aligned correctly with the tube’s entry point. Debris or buildup inside the tube can also obstruct the dipstick’s path, preventing smooth insertion.

A clean and straight dipstick is crucial for accurate oil level readings, ensuring your engine runs smoothly. Regular maintenance and careful handling can help avoid these issues, keeping your car in optimal condition and saving you from unnecessary hassle.

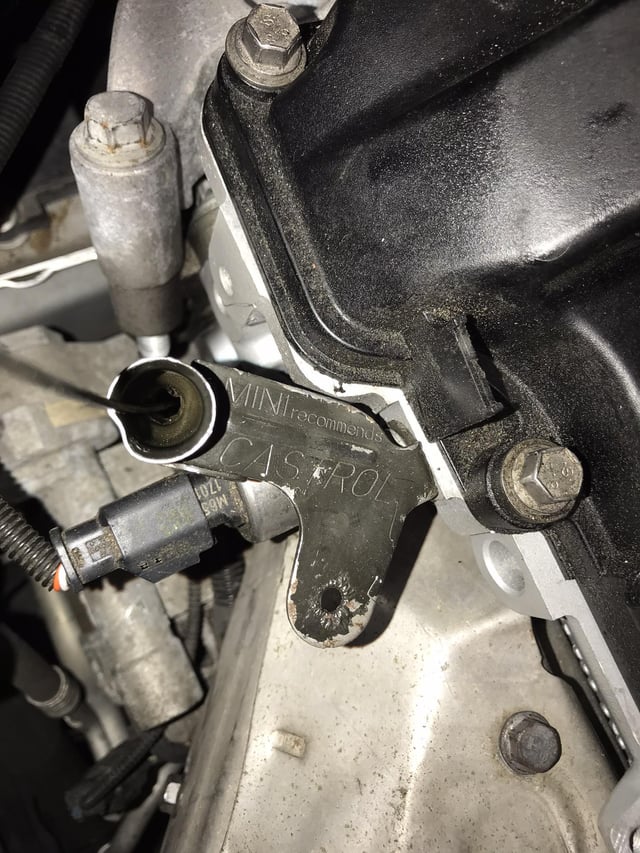

Credit: www.reddit.com

Introduction To Oil Dipstick Challenges

Oil dipsticks are essential for checking oil levels in your car. Sometimes, the dipstick won’t go back in. This problem can be frustrating. Understanding why this happens can save time and effort. Let’s explore the common dipstick issues and the importance of accurate oil levels.

Common Dipstick Issues

There are several reasons why your oil dipstick won’t go back in. Here are the most common issues:

- Debris in the tube: Dirt or debris can block the dipstick tube.

- Bent dipstick: The dipstick may be bent and not align correctly.

- Misalignment: The dipstick may not be aligned with the tube.

Importance Of Accurate Oil Levels

Accurate oil levels are crucial for your car’s health. Here’s why:

- Engine performance: Correct oil levels ensure the engine runs smoothly.

- Prevent damage: Low oil can cause engine parts to wear out faster.

- Extend engine life: Proper oil levels extend the life of your engine.

Ensuring your oil dipstick works correctly is vital. This guarantees you can monitor oil levels accurately. Keeping your engine healthy depends on this simple tool.

Credit: community.cartalk.com

Identifying The Problem

So, your oil dipstick won’t go back in? This can be a frustrating issue. Knowing the cause is the first step to fixing it. Let’s dive into the possible problems.

Physical Obstructions

Physical obstructions can block the dipstick’s path. Dirt, debris, or sludge might be the culprits. If you see any dirt, clean the dipstick tube. Use a clean cloth or a small brush. Make sure the tube is clear of any blockages.

Sometimes, the dipstick tube gets bent. A bent tube can prevent the dipstick from going in. Look closely at the tube. If it’s bent, you may need to straighten it. Use gentle force to avoid breaking it.

Misalignment Troubles

Misalignment is another common issue. The dipstick might not align with the tube correctly. This can happen if the dipstick is not inserted at the right angle. Check the angle of insertion. The dipstick should go in straight and smoothly.

Also, make sure the dipstick handle is in the right position. Sometimes, the handle can twist or turn. This makes it hard to insert the dipstick. Hold the handle firmly and guide it into the tube.

If you still face issues, consider checking the dipstick itself. Sometimes, the dipstick may get damaged. Look for any bends or breaks. A damaged dipstick can be the cause of the problem.

| Possible Causes | Solutions |

|---|---|

| Dirt or debris | Clean the dipstick tube |

| Bent tube | Straighten the tube |

| Misalignment | Check the angle and handle position |

| Damaged dipstick | Inspect and replace if necessary |

Initial Assessment

Experiencing trouble with your oil dipstick can be frustrating. The first step to solving this issue is to perform an initial assessment. This process will help identify the root cause and guide you towards a solution.

Visual Inspection Tips

Begin with a thorough visual inspection of the dipstick and its tube. Check for any visible bends or kinks in the dipstick. Ensure the dipstick is clean and free of debris.

Next, inspect the dipstick tube. Look for any obstructions or damage that might prevent the dipstick from sliding in smoothly. If the tube appears bent or damaged, it may need to be replaced.

Safety Precautions

Always prioritize safety when working on your vehicle. Here are some essential safety precautions to follow:

- Ensure the engine is off and cool before starting your inspection.

- Wear protective gloves to avoid cuts and scrapes.

- Keep the area well-ventilated to avoid inhaling fumes.

These steps will help ensure a safe and effective assessment.

| Inspection Area | Action |

|---|---|

| Dipstick | Check for bends, kinks, and debris. |

| Dipstick Tube | Inspect for obstructions or damage. |

By following these tips and precautions, you can effectively diagnose why your oil dipstick won’t go back in. Start with a thorough visual inspection and always prioritize safety.

Simple Solutions To Try

If your oil dipstick won’t go back in, don’t worry. There are simple steps you can try at home. Often, the issue is minor and can be fixed quickly. Here are two easy solutions to consider.

Cleaning The Dipstick

A dirty dipstick can cause problems. Clean the dipstick thoroughly before reinserting it. Follow these steps:

- Remove the dipstick carefully.

- Use a clean rag to wipe off any oil and dirt.

- Check for any signs of damage or bends.

- Reinsert the clean dipstick slowly and gently.

Cleaning the dipstick can often solve the problem. A clean dipstick slides back in more easily.

Lubricating The Tube

Sometimes, the tube needs lubrication. Lubricate the tube to make it easier to insert the dipstick. Here is how:

- Use a small amount of engine oil or WD-40.

- Apply the lubricant to a clean cloth.

- Wipe the inside of the tube gently.

- Insert the dipstick slowly and check if it goes in smoothly.

Lubricating the tube can reduce friction. This makes it easier for the dipstick to slide in.

Ensuring Proper Technique

Struggling to put your oil dipstick back in can be frustrating. Understanding the proper technique can help. Let’s explore the best ways to ensure your dipstick slides in smoothly.

Correct Insertion Angles

Angle matters when inserting the dipstick. Align it correctly with the tube. If the dipstick is tilted, it won’t go in. Check the angle and adjust as needed.

| Step | Action |

|---|---|

| 1 | Hold the dipstick straight. |

| 2 | Align with the tube opening. |

| 3 | Gently slide it in. |

Avoiding Forced Entry

Never force the dipstick. Forcing can cause damage. If it resists, pull it out and check again.

- Clean the dipstick before trying again.

- Check for obstacles in the tube.

- Ensure the tube is straight and not bent.

Following these steps can help your dipstick go back in smoothly without causing harm.

When To Seek Professional Help

Sometimes, the oil dipstick won’t go back in because of complex issues. These issues need expert attention. Knowing when to seek professional help is essential.

Recognizing Complex Issues

If you feel resistance or the dipstick gets stuck, it may indicate a more serious problem. This can include issues like a bent tube or internal engine problems. Don’t force the dipstick. Forcing it can cause more damage.

Another sign of a complex issue is if the dipstick shows signs of wear or damage. Visible cracks or bends on the dipstick can affect its function. These signs mean you need a professional’s help.

Unusual noises or vibrations when inserting the dipstick are also red flags. These could indicate internal engine problems that require a mechanic’s expertise.

Finding A Trusted Mechanic

Finding a reliable mechanic is crucial for resolving complex dipstick issues. Look for certified professionals with good reviews. Certifications ensure they have the right skills.

Ask friends and family for recommendations. Personal referrals often lead to trustworthy mechanics. Check online reviews as well. Positive reviews indicate reliable service.

When visiting a mechanic, ask questions about their experience with dipstick issues. A knowledgeable mechanic will explain the problem and the solution clearly. This transparency builds trust.

Compare prices from different mechanics. This helps you get the best service for a fair price. Don’t choose the cheapest option without checking their reputation.

Here is a simple table to summarize when to seek professional help:

| Signs | Action |

|---|---|

| Resistance or Stuck Dipstick | Seek professional help |

| Visible Cracks or Bends | Consult a mechanic |

| Unusual Noises or Vibrations | Get expert advice |

| Positive Online Reviews | Choose a mechanic |

Remember, addressing dipstick issues promptly can prevent further engine damage. Always seek professional help when needed.

Preventative Measures

Ensuring your oil dipstick functions smoothly is crucial for your vehicle’s health. By taking preventative measures, you can avoid issues and keep your car in top shape. Below, we delve into two key areas: routine maintenance and regular cleaning.

Routine Maintenance

Routine maintenance is essential for the longevity of your vehicle. Here are some steps to follow:

- Check your oil levels regularly. This prevents the dipstick from getting stuck due to low oil.

- Ensure that your oil is replaced at recommended intervals. Old oil can become thick and cause issues.

- Inspect the dipstick for any signs of wear and tear. Replace it if necessary.

Regular Cleaning

Keeping the dipstick and its tube clean is vital. Dirt and grime can cause blockages. Follow these steps:

- Wipe the dipstick with a clean, dry cloth each time you check the oil.

- Use a suitable cleaner to clean the dipstick tube periodically. This ensures no debris builds up.

- Ensure the dipstick is always inserted properly after cleaning.

A clean dipstick and tube ensure smooth operation. This also helps in getting accurate oil level readings.

Credit: www.reddit.com

Conclusion: Maintaining Your Vehicle

Maintaining your vehicle is essential for its longevity and performance. Simple tasks like checking the oil dipstick should not be overlooked. Regular maintenance can save you from costly repairs. Let’s dive into some key tips and the importance of being vigilant.

Summary Of Tips

- Check your oil level regularly to ensure your engine runs smoothly.

- Clean the dipstick before reinserting it to get an accurate reading.

- Inspect the dipstick tube for any obstructions or bends.

- Use the correct type of oil for your vehicle to avoid issues.

- Consult your vehicle manual for specific maintenance guidelines.

The Value Of Vigilance

Being vigilant about your vehicle’s maintenance can prevent major issues. Regular checks help identify problems early. Early detection can save time and money. Keep an eye on fluid levels and tire pressure. Ensure all components are in good working order.

Regular maintenance keeps your vehicle running efficiently. It extends the life of your car. Neglecting simple tasks can lead to bigger problems. Stay proactive and attentive. Your vehicle will thank you.

Frequently Asked Questions

How Do You Put A Dipstick Back In?

To put a dipstick back in, align it with the tube, then gently slide it down until fully seated.

What Causes An Oil Dipstick To Get Stuck?

Rust, debris, or dried oil can cause an oil dipstick to get stuck. Misalignment or a bent dipstick also contribute.

Can You Drive Without A Dipstick In?

Driving without a dipstick is not recommended. It can lead to oil contamination and engine damage. Always ensure the dipstick is in place.

Why Does My Oil Dipstick Keep Coming Out?

Your oil dipstick may keep coming out due to excessive crankcase pressure, a faulty dipstick tube, or engine vibrations. Check for blocked PCV valve or worn engine mounts.

Conclusion

Ensuring your oil dipstick goes back in smoothly is essential for accurate oil level readings. Regular maintenance and proper handling can prevent issues. Always check for obstructions and keep the dipstick clean. By following these tips, you can maintain your vehicle’s health and avoid costly repairs.