The correct tension on a flat belt ensures optimal performance and longevity. It should be just enough to prevent slipping.

Flat belts are essential in various mechanical systems, transmitting power efficiently between pulleys. Maintaining the correct tension is crucial for ensuring optimal performance and extending the lifespan of both the belt and the machinery. Too much tension can cause excessive wear on the belt and the pulleys, while too little can lead to slippage and inefficient power transmission.

Regular inspection and adjustment are necessary to keep the belt in good working condition. Using a tension gauge can help achieve the ideal tension. Proper maintenance can save costs and prevent downtime, making it a critical aspect of machinery care.

Introduction To Flat Belt Tension

Flat belt tension is very important for the belt’s performance. A belt needs the right tension to work well. Too loose or too tight can cause problems. The correct tension helps the belt to stay in place. It also makes sure the belt moves smoothly. Proper tension can also make the belt last longer.

Tension affects how the belt works. Good tension means the belt runs well. It transfers power efficiently. With the right tension, the belt will not slip. It will also not wear out quickly. This helps machines work better.

Improper belt tension can cause many issues. A loose belt may slip off. It can also cause noise and reduce power transfer. A tight belt can wear out quickly. It may also damage the machine’s parts. Both loose and tight belts can lead to higher maintenance costs.

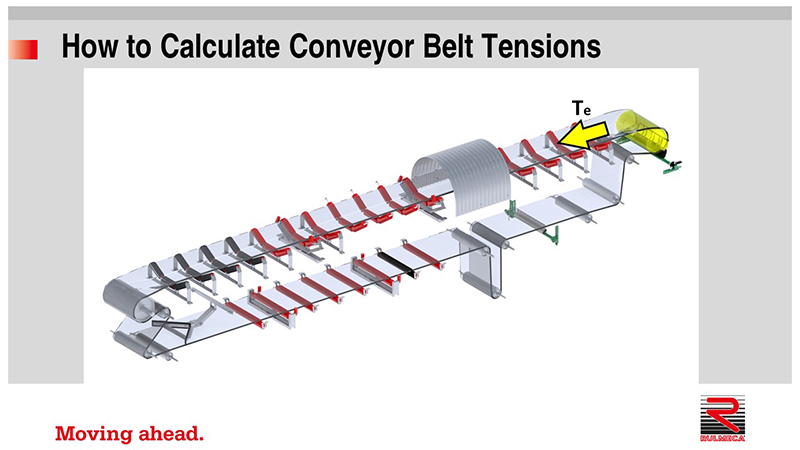

Credit: rulmecacorp.com

Measuring Belt Tension

Proper tools are needed to measure belt tension accurately. A tension gauge is the most common tool. Another tool is a deflection method ruler. Some people use a spring scale. Each tool gives different results. Always follow the manufacturer’s guidelines. This ensures the best results.

First, turn off the machine. Then, locate the belt you want to measure. Place the tension gauge on the belt. Read the measurement on the gauge. Compare this with the recommended tension. Adjust the belt if needed. Sometimes you need to repeat the process. This ensures the tension is correct.

Calculating Optimal Tension

The correct tension ensures the belt works well. You need to know some key formulas. The formula for tension is T = F / W. Here, T stands for tension, F is force, and W is width. Variables like belt speed and pulley size also affect tension. Using these formulas, you can find the best tension level. Always check the belt’s specifications for accurate values.

Industry standards help maintain belt performance. Most standards recommend checking tension regularly. Use a tension gauge for the best results. Follow the manufacturer’s guidelines for specific tension ranges. Proper tension reduces wear and tear on the belt. This helps the belt last longer and work better.

Credit: www.chegg.com

Adjusting Belt Tension

Manual adjustment techniques involve using tools to set the belt tension. First, loosen the bolts on the motor base. Slide the motor to adjust the belt tension. Use a tension gauge to measure the tension. The belt should not be too tight. It should also not be too loose. Check the belt regularly for wear and tear. This ensures the belt lasts longer.

Automated tensioning systems use sensors to adjust the belt tension. These systems are more accurate. They reduce the need for manual checks. The system adjusts tension based on belt load. This ensures consistent tension at all times. Automated systems are more expensive. They offer better performance and less maintenance. These systems are ideal for heavy-duty applications.

Effects Of Temperature And Humidity On Belt Tension

Proper belt tension is crucial for flat belts, as temperature and humidity can significantly impact performance. Maintaining correct tension ensures optimal efficiency and longevity.

Environmental Factors To Consider

Temperature changes can affect belt tension. A belt can expand in high temperatures. Cold temperatures can cause a belt to contract. Humidity also plays a role. High humidity can make belts absorb moisture. This can lead to slack in the belt. Low humidity can make the belt dry and brittle.

Adjusting Tension For Climate Variations

Regular checks are essential for proper belt tension. Adjust the belt during different seasons. Check the belt in summer and winter. Make sure the tension is consistent. Use a tension meter for accuracy. Proper tension helps in smooth operations. It also increases the belt’s lifespan.

Regular Maintenance And Tension Checks

Ensuring proper tension on a flat belt is crucial for optimal performance and longevity. Regular maintenance and tension checks help prevent slippage and excessive wear, enhancing efficiency.

Maintenance Schedule For Optimal Performance

Regular maintenance ensures your flat belt performs well. Check the belt tension every week. Make sure the belt is clean and free from dirt. Inspect for wear and tear every month. Replace the belt if it shows signs of damage. Lubricate the pulley system regularly. This helps in reducing friction. Keep a maintenance log to track all checks and adjustments.

Troubleshooting Common Tension Issues

If the belt slips, the tension might be too loose. Tighten the belt by adjusting the tensioner. If the belt makes noise, it could be too tight. Loosen the belt a bit and check again. A misaligned pulley can also cause problems. Ensure the pulley is aligned properly. Check for any debris that might be causing issues. Remove any foreign objects immediately. Regular inspections can prevent most tension problems.

Case Studies: Tension Optimization In Different Industries

Proper tension in flat belts is crucial in manufacturing. It impacts the efficiency of conveyor belt systems. Over-tensioning can cause excessive wear and tear on the belt. This leads to higher maintenance costs and downtime. On the other hand, under-tensioning results in slippage and misalignment. This reduces the system’s productivity.

Manufacturers must regularly check the tension to ensure optimal performance. They often use tension meters or force gauges for this purpose. By maintaining the correct tension, the lifespan of the belt is extended. This ensures smooth and efficient operations in the manufacturing process.

Impact Of Tension On Conveyor Belt Systems

Conveyor belt systems in manufacturing rely heavily on correct tension. It affects the system’s load-carrying capacity and speed. Incorrect tension can lead to belt slippage, causing delays in production. It also increases the risk of belt breakage and system failure.

Maintaining the right tension can optimize energy consumption. It reduces the strain on motors and other components. Proper tension also minimizes the risk of accidents and injuries. This creates a safer working environment for employees.

Conclusion: Ensuring Peak Performance

Maintaining the correct tension on a flat belt is crucial. It ensures the belt runs smoothly. Regular checks are important for keeping the tension right. Use a tension gauge to measure it. Keep the belt clean to avoid slippage. Proper alignment of the pulleys is also necessary. Misalignment can cause wear and tear. Lubricate the belt as needed to reduce friction. This helps in extending the belt’s life.

Best Practices For Long-term Success

Check the tension regularly. Clean the belt often. Align the pulleys properly. Use a tension gauge. Lubricate the belt. Avoid overloading the belt. Store the belt in a cool, dry place. Replace worn belts immediately. Train staff on maintenance.

Future Innovations In Belt Tension Technology

Automatic tensioning systems are being developed. These systems adjust the tension automatically. They use sensors to monitor the belt. The systems reduce manual checks. They improve efficiency and safety. Smart belts with built-in sensors are also emerging. These belts provide real-time data. This helps in proactive maintenance. The innovations aim to extend belt life. They also aim to reduce downtime.

Credit: fmhconveyors.com

Frequently Asked Questions

What Is The Correct Tension For A Flat Belt?

The correct tension for a flat belt depends on the belt type and application. Follow the manufacturer’s recommendations. Proper tension ensures efficient operation and longevity. Use a tension gauge for accurate measurement.

What Is The Proper Belt Tension?

Proper belt tension ensures optimal performance. Adjust until the belt deflects about half an inch under firm finger pressure. Check the manufacturer’s specifications for precise measurements. Regularly inspect and adjust to maintain efficiency and prevent wear.

What Is The Initial Tension In The Flat Belt?

The initial tension in a flat belt is the tension applied before the belt starts operating. This ensures proper grip and efficient power transmission. Proper initial tension prevents slippage and extends belt life.

What Is The Rule Of Thumb For Belt Tension?

A good rule of thumb for belt tension is to twist the belt halfway between pulleys. It should twist 90 degrees.

Conclusion

Achieving the correct tension on a flat belt is crucial for optimal performance. Proper tension ensures efficiency and longevity. Regular checks and adjustments prevent excessive wear and potential failures. By following the guidelines mentioned, you can maintain your belt system effectively.

Always prioritize correct tension for smooth and reliable operations.