Hot spots on rotors are caused by uneven heating and cooling cycles. This occurs when the rotor is spinning at high speeds and heat is generated from friction between the pads, caliper, and rotor. As the system heats up, some areas of the brake pad will be hotter than others due to different braking forces being applied in certain areas.

When this happens, it causes hot spots on the rotor which can reduce stopping power or cause vibrations while driving. The best way to prevent hot spots is to make sure that your brakes are properly adjusted so that all surfaces contact evenly throughout braking events. Additionally, using higher quality brake pads can also help as these typically have better heat dissipation properties.

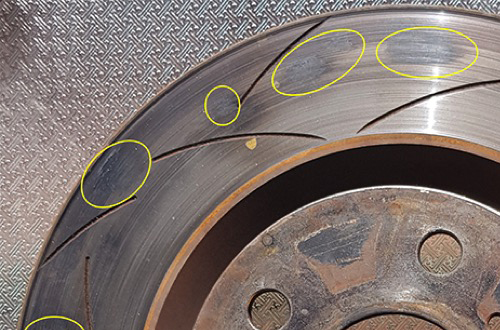

Rotor Has Seen Their Better Days | Hot Spots On Rotor Bad Brake Caliper & How To Spot A Bad Caliper

Hot spots on rotors are caused by a combination of high temperatures, uneven friction and inadequate lubrication. The frictional heat generated from the contact between the rotor and brake pad causes the rotor to expand unevenly across its surface. This leads to hot spots that can cause excessive wear on both the pads and rotors, resulting in reduced braking performance.

To reduce these hot spots it is important to ensure your brakes are kept properly lubricated and that you regularly inspect them for any signs of wear or damage.

How to Get Rid of Hot Spots on Rotors

Hot spots on rotors can be difficult to get rid of, but fortunately there are a few steps you can take to help. First, make sure that the rotor is properly aligned and balanced. This will help reduce vibrations and prevent additional hot spots from forming.

Second, if your brakes have been recently replaced or adjusted, it’s important to bed them in correctly – this means slowly increasing your speed while braking lightly multiple times so that the pads and rotors heat up evenly. Finally, use an abrasive material like sandpaper or steel wool to remove any glazing or corrosion from the rotor surface – this should eliminate most existing hot spots.

Credit: www.reddit.com

How Do I Prevent Hot Spots on My Brakes?

When it comes to preventing hot spots on your brakes, the most important thing to remember is regular maintenance. Make sure you check your brake pads and rotors every 10,000 miles or so for any signs of wear or damage. Also make sure that you use the correct type of brake pads and rotors for your vehicle – some vehicles require specific types that are designed to reduce heat buildup.

Additionally, regularly inspect all other components related to the braking system such as hoses, calipers, and cylinders for any signs of excessive wear or damage which may cause a hot spot. Finally, if possible try not to apply too much pressure when braking as this can also lead to overheating issues; instead opt for a gentle application whenever possible. By following these simple tips you should be able to keep your brakes in top condition and prevent hot spots from occurring!

Do I Need to Replace Rotors With Hot Spots?

When considering whether or not you need to replace rotors with hot spots, the answer is largely dependent on your vehicle and its needs. Hot spots are an area of increased friction that can occur due to uneven wear or grooves in a brake rotor. If these areas have become too deep, they may cause vibration when braking.

This can be dangerous as it interferes with the driver’s ability to operate the vehicle safely. It is also important to consider how often you use your brakes and how hard you press down on them—this can contribute to wearing out your rotors faster than normal, which could lead to having hotspots form more quickly than usual. Ultimately, if there are noticeable issues such as vibrations while braking or odd noises coming from the brakes then it would be best for safety reasons (and peace of mind) to replace any worn-out brake rotors with new ones that do not contain hot spots.

Can You Machine Rotors With Hot Spots?

Yes, you can machine rotors with hot spots. This process is known as dynamic balancing and involves the use of specialized equipment that detects and measures any imbalance in a rotating component. The aim is to reduce or eliminate unbalanced forces generated from the rotor itself by adjusting its mass distribution until it has an even weight distribution around its axis of rotation.

Hot spots occur when there are imbalances in the mass distribution, which can be caused by manufacturing defects such as out-of-roundness or misaligned parts. By machining these areas down, it allows for better balance to be achieved on the rotor, reducing vibration levels and increasing efficiency. In addition to machining hot spots, other processes may also need to be carried out such as grinding or polishing depending on the severity of the issue being addressed.

Dynamic balancing should always be performed after any machining operations have been completed so that all corrections are accounted for before final assembly takes place.

Conclusion

In conclusion, hot spots on rotors are caused by a variety of factors including poor bedding in of brake pads, the caliper sticking or seizing and uneven wear due to over-tightening or misalignment. Hot spots can cause vibration and reduced braking power. To prevent them from occurring it is important to check for proper alignment, pad seating and examine the brakes regularly for signs of wear.

Proper maintenance will help ensure that your vehicle’s rotors remain free from hot spots.