A winch motor is a critical component of any winching system, responsible for providing the power needed to pull heavy loads. However, like any mechanical device, it can experience wear and tear over time.

Identifying the early signs of a failing winch motor is crucial to avoid equipment failure during critical operations. Knowing how to tell if a winch motor is bad can help you troubleshoot problems, prevent further damage, and ensure the winch performs reliably.

This guide will walk you through common symptoms of a faulty winch motor and how to diagnose potential issues before they become serious.

A faulty winch motor can lead to performance issues or even complete failure during use, so it’s essential to identify signs of trouble.

Here’s How You Can Tell If a Winch Motor is Bad:

1. Motor Won’t Run

If the winch motor doesn’t turn on when power is applied:

- Check power supply: Ensure the battery or power source is working correctly and has enough charge.

- Inspect wiring: Loose, frayed, or corroded wires can prevent the motor from receiving power.

- Test the motor directly: Use jumper cables to bypass the solenoid and connect the motor directly to the battery. If it still won’t run, the motor may be bad.

2. Weak or Slow Performance

If the winch motor runs but seems weak or slow, it could indicate:

- Worn motor brushes: Over time, the carbon brushes inside the motor wear down, reducing contact with the commutator, which leads to a loss of power.

- Low voltage: Check if the battery or power source is delivering enough voltage. A low or insufficient power supply can cause sluggish performance.

- Damaged windings: If the motor windings are burnt or damaged, the motor may still turn but will do so slowly or with reduced torque.

3. Strange Noises

Unusual noises, such as grinding, clicking, or whining, can indicate:

- Worn bearings: If the bearings inside the motor are worn out, it can cause friction and noise.

- Damaged gears: If the winch motor’s gears are damaged, it may produce grinding or other mechanical noises.

- Internal motor damage: Loose or damaged parts inside the motor can lead to rattling or other irregular noises.

4. Motor Overheating

If the winch motor gets excessively hot during operation, this may be a sign of:

- Excessive current draw: A damaged motor can draw too much current, causing it to overheat.

- Worn bearings: Friction from worn bearings can generate excessive heat.

- Internal short: A short in the motor windings can cause it to overheat quickly during use.

5. Burnt Smell

A burning smell coming from the motor usually indicates:

- Burnt windings: Overheating or an internal short can burn the motor windings, emitting a burnt odor.

- Fried components: If electrical components such as brushes or the commutator are burnt or damaged, they may give off a distinct smell.

6. Inconsistent Operation

If the winch motor works intermittently or stops and starts unexpectedly:

- Faulty brushes or commutator: Worn brushes or a damaged commutator may cause inconsistent electrical contact, leading to intermittent operation.

- Loose connections: Check for loose wiring, terminals, or poor connections in the motor or control system.

- Solenoid failure: If the solenoid is malfunctioning, it may not consistently send power to the motor. so test your solenoid properly.

7. High Amp Draw

If your winch motor draws more amps than it should during normal operation, it can indicate:

- Internal motor damage: Shorted windings, damaged brushes, or mechanical drag from worn bearings can cause the motor to draw excessive power.

- Mechanical resistance: If the winch is under excessive load or has internal binding, it can cause the motor to draw more current.

8. No Movement Under Load

If the motor runs but the winch doesn’t pull or struggles under load:

- Damaged or stripped gears: The motor might spin, but if the gears are stripped or damaged, the winch won’t pull properly.

- Weak motor: A worn-out motor might not have enough power to handle a heavy load.

Step-by-Step Diagnosis

- Check the power supply: Verify the battery is fully charged and that all electrical connections are solid.

- Test the motor with jumper cables: Connect the motor directly to a battery to see if it runs. If not, the motor is likely bad.

- Use a multimeter: Check for continuity in the motor windings and test for electrical shorts or opens in the motor.

- Inspect for physical damage: Open the motor casing (if possible) and check for worn brushes, damaged windings, or broken components.

By performing these checks, you can determine if your winch motor is faulty and whether it needs repair or replacement.

Credit: boostatv.com

Why Won’t My Winch Engage?

If your winch won’t engage, it could be for a number of reasons. The first thing you should check is the power source. Make sure the battery is fully charged and that the connections are clean and secure.

If the battery is good, then check the solenoid. The solenoid is what controls the flow of electricity to the winch motor. If it’s defective, it will need to be replaced.

Another possibility is that the clutch is slipping. This can be caused by worn out bearings or a damaged clutch plate. If this is the case, you’ll need to replace those parts as well.

Lastly, if none of these things are an issue, then it’s possible that there’s something wrong with the winch motor itself. In any case, if your winch won’t engage, it’s best to take it to a qualified technician who can diagnose and fix the problem.

How Do You Test a Winch Solenoid With a Multimeter?

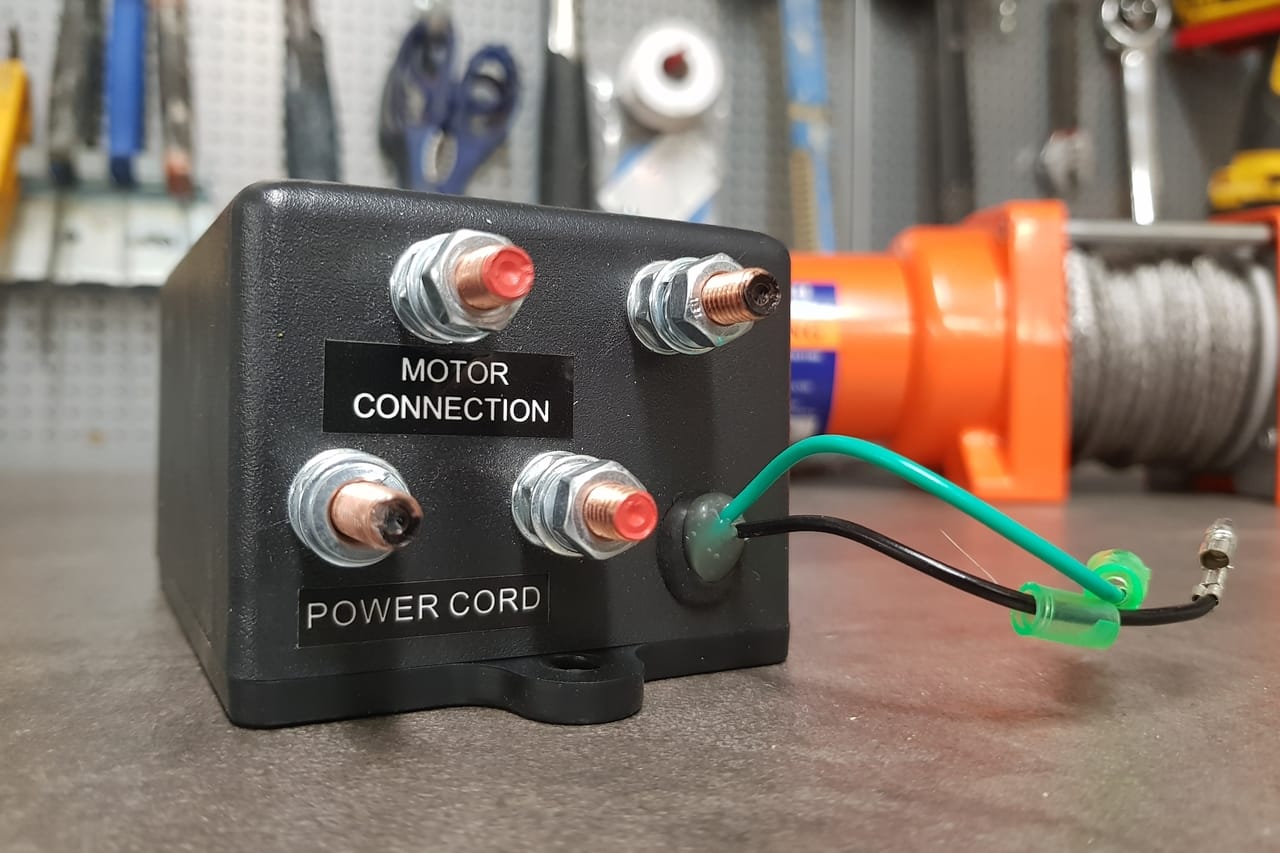

A winch solenoid is an electromechanical device that controls the flow of electricity to the winch motor. It is usually located in the engine compartment, near the battery. The solenoid consists of a coil of wire wrapped around a iron core, with a switch attached to the end of the coil.

When the switch is turned on, current flows through the coil and creates a magnetic field. This magnetic field pulls on the armature, which opens the switch and allows current to flow to the motor. To test a winch solenoid with a multimeter,

first disconnect the negative (-) terminal from the battery.

Then set your multimeter to Ohms mode and touch one probe to each of the small terminals on the solenoid (these are typically labeled “S” and “I”).

If there is continuity between these terminals, then your solenoid is good. If there is no continuity, then your solenoid is bad and needs to be replaced.

Why Does My Winch Only Work in One Direction?

There are a few reasons your winch might only work in one direction. The first possibility is that the motor is only wired to run in one direction. This can be easily checked by reversing the battery cables on the winch.

If the motor still only runs in one direction, then it is likely that the brushes inside the motor are worn out and need to be replaced. Another possibility is that the solenoid, which controls current flow to the motor, is sticking or damaged. This can be checked by manually engaging and disengaging the solenoid while watching the contact points.

If they do not line up properly, or if there is visible damage to the solenoid, it will need to be replaced. Finally, it is also possible that something is preventing the spool from turning freely. This could be debris caught in between the spool and housing, or a damaged/stripped gear inside the winch.

Inspecting and cleaning/repairing/replacing these parts should fix the problem.

How to Test a 2 Post Winch Motor

If you’re having trouble with your 2 post winch motor, there are a few things you can do to test it and see what’s wrong.

First, check the battery to make sure it’s charged.

Next, check the connections between the battery and the motor to make sure they’re tight.

If everything looks good there, try testing the motor by running a rope or cable through it and seeing if it will lift a heavy object. If the motor still isn’t working, it may need to be replaced.

Conclusion

If you have a winch, it’s important to know how to tell if the motor is bad. There are a few things you can look for to determine if your winch motor is going bad. First, check the brushes.

If they’re worn down, it’s a sign that the motor is going bad. Second, check the terminals. If they’re corroded or damaged, it means the motor is having trouble transferring power.

Finally, listen for strange noises coming from the motor. If you hear anything unusual, it’s likely that the motor is going bad and needs to be replaced.