Boost pressure reading is crucial for diagnosing a vehicle’s performance issues. Many modern vehicles use turbochargers to enhance power and efficiency. The boost pressure indicates how much extra air the turbocharger forces into the engine. Accurate readings help identify potential problems like turbocharger failures, leaks, or engine inefficiencies.

Using an OBD-II scanner simplifies this process by providing real-time data. Mechanics and DIY enthusiasts can monitor the turbo system’s health. Regular checks ensure optimal vehicle performance and fuel efficiency. Understanding boost pressure aids in maintaining engine longevity and overall vehicle reliability.

Credit: forum.hptuners.com

How to Read Boost Pressure on Scanner

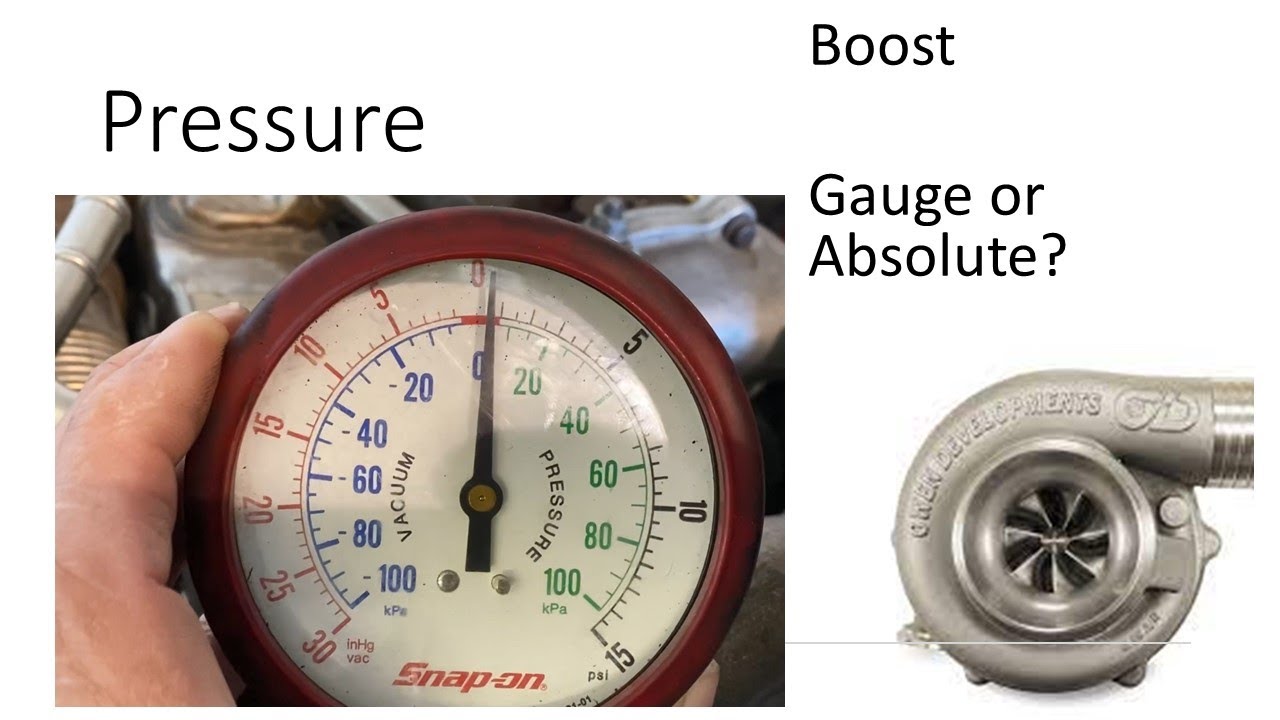

Boost pressure refers to the amount of pressure generated by a turbocharger or supercharger that forces more air into the engine, increasing power output. Many modern vehicles equipped with turbochargers allow you to monitor this important parameter through an OBD2 scanner.

In this guide, you’ll learn how to read boost pressure using an OBD2 scanner and understand what it means for your vehicle’s performance.

Tools You Will Need:

- An OBD2 scanner with real-time data monitoring capability (many scanners can show boost pressure)

- A compatible vehicle with a turbocharged or supercharged engine

Step-by-Step Guide to Reading Boost Pressure on an OBD2 Scanner

1. Turn On Your Vehicle

- Ensure your vehicle is in ignition mode. For vehicles with push-button start, press the start button without pressing the brake to enter accessory mode. This powers up the electronics without starting the engine.

2. Plug in the OBD2 Scanner

- Connect your OBD2 scanner to the OBD2 port. This port is usually located beneath the dashboard on the driver’s side.

- Once plugged in, the scanner should automatically power up.

3. Access Live Data Mode

- Navigate to the “Live Data” or “Real-Time Data” section in the scanner’s menu. This mode allows you to monitor various parameters from the vehicle’s engine control unit (ECU) in real-time.

4. Find the Boost Pressure Parameter

- Depending on your vehicle and OBD2 scanner, the boost pressure may be listed under different names:

- Boost Pressure

- Intake Manifold Absolute Pressure (MAP)

- Turbo Boost

- Manifold Pressure

- Boost Vacuum

Look for these terms in the list of live data parameters.

5. Read the Boost Pressure

- Once you locate the correct parameter, you can see the real-time reading of your vehicle’s boost pressure.

- Most scanners will display this value in PSI or BAR, and the number will vary depending on the driving conditions (e.g., idling vs. accelerating).

6. Understand the Readings

- At Idle or Low Throttle: You may see a negative value, indicating vacuum rather than positive boost pressure. This is normal when the turbocharger is not actively forcing air into the engine.

- Under Acceleration: As the turbo kicks in, you should see the boost pressure rise. On most turbocharged vehicles, this will range from 5 to 15 PSI, though performance cars may show much higher values.

7. Evaluate the Readings

- Compare the observed boost pressure to your vehicle’s specifications. If the boost pressure is too high, it can indicate potential over-boost, which can harm your engine.

- Low Boost Pressure could be caused by leaks in the intake system, a faulty turbocharger, or sensor issues.

Key Considerations When Reading Boost Pressure

-

Units of Measurement: Boost pressure is commonly displayed in PSI (pounds per square inch) in the U.S., while some OBD2 scanners may use BAR (1 BAR = 14.5 PSI). Be sure you know the units your scanner is using to interpret the readings correctly.

-

Turbo Lag: If you notice that the boost pressure doesn’t rise immediately when accelerating, this could be due to turbo lag, which is the time it takes for the turbocharger to spool up.

-

Boost Spike: Temporary boosts above the normal range (boost spikes) can occur, especially in tuned vehicles. Monitor your boost levels carefully if your vehicle has been modified.

-

Vacuum at Idle: Seeing negative values (vacuum) while idling or coasting is normal. Boost only occurs when the engine needs extra air under load.

Common Issues You Might Detect:

- Under-Boost Condition: If your OBD2 scanner shows consistently low boost pressure, this could point to:

- A leaking hose or intercooler.

- Wastegate or blow-off valve problems.

- Faulty turbocharger.

- Over-Boost Condition: If your boost pressure exceeds the manufacturer’s specification, it may indicate:

- A stuck wastegate.

- Faulty boost control solenoid.

- Engine tuning issues that require adjustment.

Advanced Scanners and Apps for Boost Pressure

If you’re using an OBD2 scanner with Bluetooth connectivity, you can use apps like Torque Pro (for Android) or OBD Fusion (for iOS). These apps offer a more user-friendly interface and customizable gauge displays for monitoring boost pressure.

Importance Of Accurate Readings

Boost pressure is crucial for engine performance. Accurate readings ensure the engine runs smoothly. Incorrect readings can lead to engine damage. Mechanics rely on precise data for diagnosing issues. Drivers need this information for optimal performance.

Monitoring boost pressure helps in maintaining efficiency. Always use a reliable scanner for readings. Double-check the data for accuracy.

Common Reading Errors And How To Avoid Them

Incorrect calibration can lead to faulty readings. Ensure your scanner is calibrated before each use. Follow the manufacturer’s instructions for calibration. Improper calibration affects the accuracy of boost pressure readings. Always double-check calibration settings. Recalibrate if necessary to get correct readings.

Temperature changes can affect boost pressure readings. Extreme heat or cold may cause inaccurate results. Keep your scanner at a stable temperature. Humidity can also impact readings. Avoid areas with high moisture levels.

Ensure clean and dry connections to the scanner. Dust and debris can interfere with readings. Keep the sensor clean and free of obstructions.

Credit: www.matthewsvolvosite.com

Credit: www.youtube.com

Frequently Asked Questions About obd2 Scanner

Can Obd2 Read Boost Pressure?

Yes, OBD2 can read boost pressure if your vehicle has a boost pressure sensor. Check your car’s specifications.

What Should A Boost Pressure Sensor Read?

A boost pressure sensor should read 12-14. 5 psi at idle and up to 20-30 psi under load, depending on the vehicle.

How Do You Measure Boost Pressure?

To measure boost pressure, use a boost gauge or a pressure sensor. Install the gauge in the intake manifold. Ensure accurate readings by calibrating the sensor properly.

How To Calculate Boost Psi?

To calculate boost PSI, use a boost gauge or sensor to measure pressure. Subtract atmospheric pressure (14. 7 PSI at sea level) from the total pressure reading.

Conclusion

Mastering how to read boost pressure on a scanner enhances vehicle performance. It aids in early problem detection, ensuring a smooth ride. Regularly monitor boost levels to maintain engine health. Utilize this skill to prolong your vehicle’s lifespan and efficiency.

Happy scanning and safe driving!