Ensuring the safety and optimal performance of a semi-truck is of paramount importance, and one critical aspect is the proper maintenance of the braking system. Brake shoes play a crucial role in the braking mechanism of a semi-truck, and accurate measurement is essential for determining when replacement is necessary.

In this guide, we will walk you through the step-by-step process of measuring semi-truck brake shoes.

Importance of Measuring Semi Truck Brake Shoes:

Brake shoes are a vital component of a drum brake system, commonly found in the rear wheels of semi-trucks. These shoes wear down over time due to friction with the brake drum, and measuring their thickness is crucial to assess their remaining lifespan. Regular measurements help prevent brake failure, ensure safe operation, and save on potential repair costs.

Tools Required to Measure Semi Truck Brake Shoes:

- Calipers: Digital or manual calipers are essential for precise measurements.

- Depth Gauge: A depth gauge allows accurate measurement of the brake shoe lining thickness.

- Brake Shoe Gauge: This specialized tool is designed specifically for measuring brake shoe lining thickness.

Step-by-Step Guide about How to Measure Semi Truck Brake Shoes:

-

Park the Truck Safely:

- Ensure the semi-truck is parked on a level surface with the parking brake engaged.

- Use appropriate safety measures, such as wheel chocks, to prevent the truck from moving.

-

Locate the Brake Drum:

- Identify the wheel with the drum brake system.

- Remove the wheel and locate the brake drum, which houses the brake shoes.

-

Inspect the Brake Shoes:

- Visually inspect the brake shoes for signs of uneven wear, cracks, or other damage.

- Ensure the drum brake components are clean and free of debris.

-

Measure Brake Shoe Lining Thickness:

- Use calipers to measure the thickness of the brake shoe lining. Take measurements at multiple points across the shoe to account for any irregular wear.

- Record the measurements for future reference.

-

Check for Manufacturer Specifications:

- Refer to the truck’s service manual or contact the manufacturer to determine the minimum allowable thickness for the brake shoe lining.

-

Use a Brake Shoe Gauge:

- A brake shoe gauge can provide a quick and accurate measurement of the lining thickness.

- Place the gauge between the brake shoe and the drum, and note the reading.

-

Check for Wear Indicator Grooves:

- Some brake shoes have wear indicator grooves. If visible, measure the depth of these grooves to assess the remaining lifespan of the brake shoe.

-

Repeat for Other Wheels:

- Repeat the measurement process for all wheels equipped with drum brakes.

Credit: waynetruck.com

How Do You Measure Brake Shoe Thickness on a Semi Truck?

Measuring the brake shoe thickness on a semi truck is an important part of maintaining your vehicle. The brake shoes are responsible for providing friction to slow and stop the wheels, thus ensuring safe operation of the truck. In order to verify that your brakes are operating at peak efficiency, you must measure their thickness periodically.

To do this, you will need a micrometer or caliper that can accurately measure small distances in millimeters or inches. Begin by removing one wheel from the axle and then remove any clips or retainers securing the brakes in place. Once these are removed, carefully inspect each braking surface for wear and tear using a flashlight if necessary before measuring it with your tool of choice.

Record all measurements as they will help identify when replacement is needed due to excessive wear and tear.

Finally, reattach any components you removed during disassembly and reinstall the wheel back onto its axle before moving onto other tires following this same procedure until all four have been checked for proper brake shoe thickness measurement on your semi-truck!

How Do You Measure Brake Shoes?

Measuring brake shoes is a fairly simple task that can be done in about five minutes with the right tools. The first step in measuring brake shoes is to remove them from the wheel hub and inspect them for cracks, gouges, or other damage. If any of these are present it may be necessary to replace the shoe instead of just measuring it.

Once you have determined that the shoe is safe to measure, you will need a pair of calipers or a micrometer. Place one end of either tool on the inside edge of one side of the shoe and then bring it around until it rests against its opposite side on the outside edge. This measurement should give you an accurate reading as to how wide your shoe’s friction surface is; any measurements below 7/8 inch would indicate wear and require replacement.

Where Do You Measure Brake Shoes on a Truck?

When it comes to measuring the brake shoes on a truck, there are several different points of measurement that can be taken. The primary measure is usually across the surface area of the two contact points on each shoe. This will help determine how much pressure is being applied and make sure that they are properly adjusted for optimal braking performance.

Additionally, you’ll want to examine both sides of the wheel hub where the brake shoes attach to ensure that everything lines up correctly and nothing has become misaligned from regular wear and tear over time. Finally, you’ll need to take measurements along both edges of the shoe itself – this helps confirm even distribution of wear and tear as well as proper tension when in use. All these measures should be done before installing any new brakes or making any adjustments so you know exactly what your starting point is for safe operation.

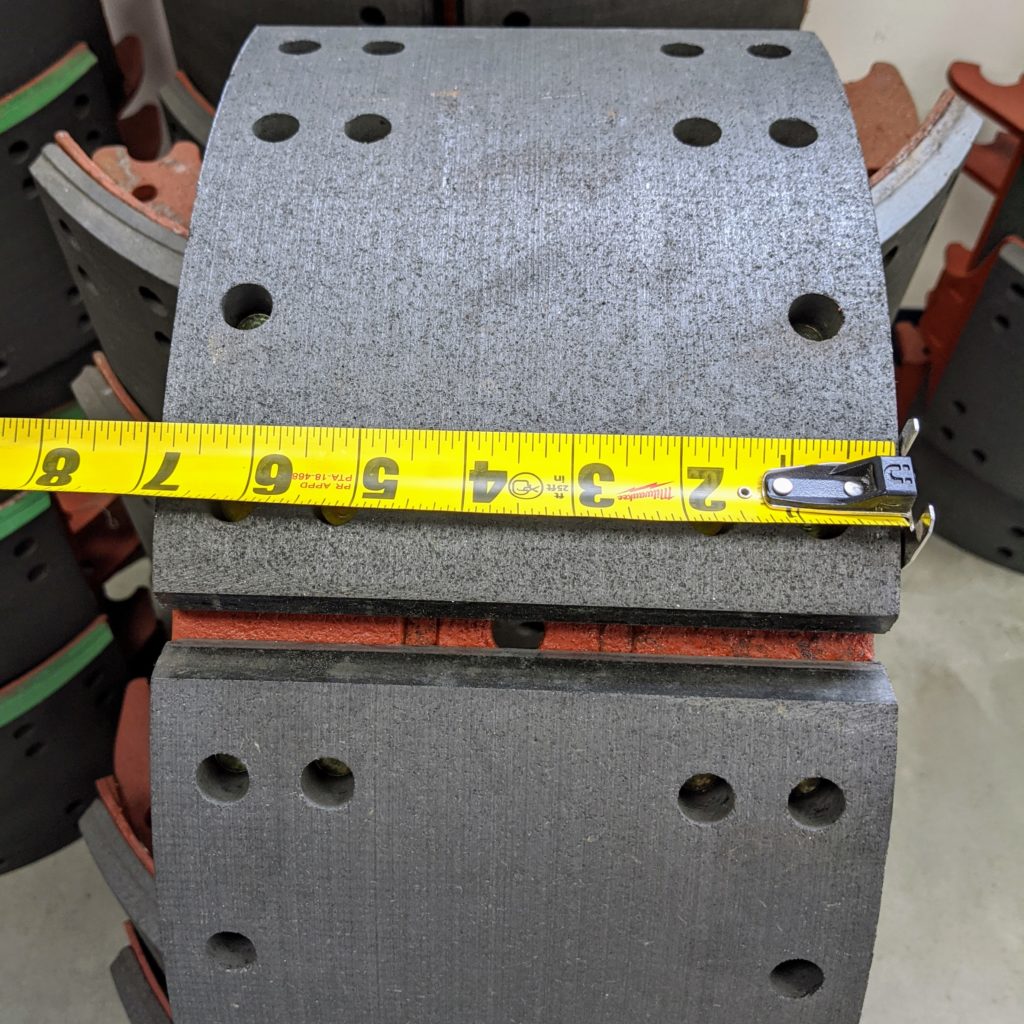

Measuring brake shoe drum brakes

Conclusion

Measuring semi truck brake shoes is not as difficult as it seems. With a few tools and some practice, anyone can accurately measure the size of their brakes. It’s important to remember that different brands will have slightly different sizes for the same brake shoe, so always double-check with your manufacturer before ordering new ones.

By following these steps and taking accurate measurements, you are sure to get precisely what you need without any costly mistakes or delays in replacing worn out brakes.