Bearing measurement is an important process that helps ensure the efficient functioning of different types of machines and equipment. By measuring bearings regularly, you can detect any wear and tear, as well as irregularities, in the bearing’s surfaces.

This measurement process enables you to identify any problems early on and ensure timely maintenance, which can extend the overall lifespan of your machinery. In this article, we will discuss some important steps and techniques for measuring bearings effectively.

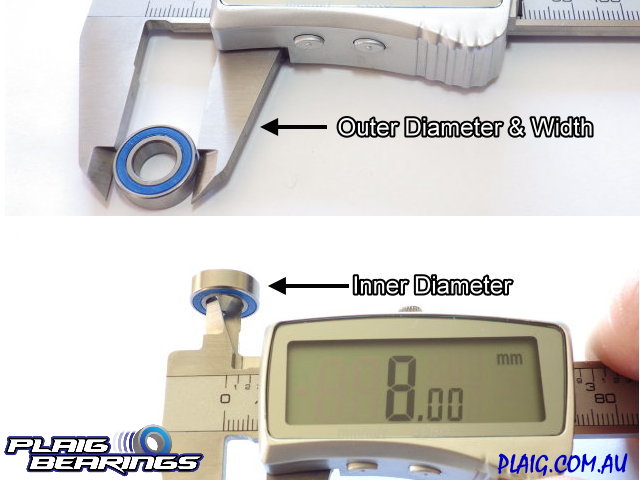

Credit: plaig.com.au

The Basics Of Bearings

Bearings are a crucial component in a wide range of machines, from automobiles to industrial equipment. Understanding the basics of bearings is essential for ensuring that they function correctly and efficiently. There are several types of bearings, including ball bearings, roller bearings, and plain bearings.

Bearings are responsible for the smooth movement of rotating or linear parts, reducing friction and wear and tear. Common applications for bearings include automotive engines, turbines, and conveyor systems. Knowing how to measure bearings can help diagnose problems and determine if replacement is necessary.

By understanding the basics of bearings, you can ensure that your machinery runs optimally and minimizes downtime.

Necessary Tools For Measuring Bearings

To properly measure bearings, it is essential to have the right tools on hand. Digital calipers, dial indicators, micrometers, and snap gauges are all necessary tools for the job. These tools help ensure accurate measurements of the bearings, which are critical to maintaining their performance and longevity.

Digital calipers provide precise and quick measurements, while dial indicators can be used to check for any runout in the bearing. Micrometers are great for measuring the inner and outer diameter of bearings, and snap gauges can verify the thickness of wires or flat surfaces.

By having these tools in your arsenal, you can confidently measure and maintain your bearings, ultimately extending their life and saving on costs in the long run.

How to measure the bearing of A from B (measuring bearings)

Step-By-Step Procedure For Measuring Bearings

Measuring bearings is a crucial step in ensuring proper functioning of machines. To get accurate measurements, you need to follow a step-by-step procedure. First, prepare by gathering the necessary tools and cleaning the bearing. Next, measure the inner diameter using a micrometer.

Then, measure the outer diameter using a vernier caliper. After that, measure the width or thickness of the bearing with the vernier caliper. Finally, calculate the bearing clearance and understand the results. By following this procedure, you can effectively measure the bearings and ensure the longevity of your machinery.

Factors Affecting Bearing Measurements

To ensure maximum efficiency and durability, it is essential to measure bearings regularly. However, several factors can affect the accuracy of measurements. Temperature fluctuations affect the size and shape of bearing components and can cause expansion or contraction. Vibration during operation can cause deflection or distortion in the bearing, leading to inaccurate measurements.

Lubrication is another critical factor affecting bearing measurements, as insufficient lubrication can result in friction, heat, and premature wear. External forces, such as improper handling or installation, can also cause changes in the bearing’s structure and affect readings. Therefore, it is crucial to consider these factors while measuring the bearing and to address and rectify any discrepancies in readings for optimal performance.

Common Mistakes To Avoid

When it comes to measuring bearings, it’s important to avoid common mistakes that could impact accuracy. One of the biggest mistakes is incorrectly using measuring tools, which can lead to inaccurate readings. Mishandling or damage to the bearing can also skew measurements.

To ensure precise measurements, it’s essential to use the appropriate tools correctly and handle the bearing carefully. Take the time to double-check measurements and avoid rushing through the process to ensure accurate results. By avoiding these common mistakes, you can measure your bearings with confidence and precision.

Frequently Asked Questions On How To Measure Bearing

How Do I Measure Bearing Size?

To measure bearing size, use a caliper to measure the inside and outside diameters and the thickness of the bearing.

What Is The Standard Unit Of Measurement For Bearings?

The standard unit of measurement for bearings is millimeters (mm).

Why Is It Important To Measure Bearing Clearance?

Measuring bearing clearance ensures proper function, reduces wear, and prolongs bearing life.

What Is The Procedure For Measuring Axial Play?

Measure axial play by fixing the bearing and pulling the shaft alternatively in the axial movement. Compare results to manufacturer’s specs.

Conclusion

Measuring bearings is a crucial process that ensures efficient and accurate functioning of various machines and systems. To achieve accurate measurements of bearings, it is important to use the right tools and techniques, including micrometers, dial indicators, and visual inspection methods.

Regular measuring and monitoring of bearings can help detect any wear and tear, as well as prevent costly repairs and replacements. With proper measurement techniques, one can ensure the optimal performance and longevity of bearings in various applications.