To line up a manual transmission to an engine, ensure the clutch is properly aligned and the transmission is centered. Slide the transmission into place carefully.

Aligning a manual transmission with an engine requires precision and patience. Proper alignment ensures the efficient operation of your vehicle. Start by securing the engine on a stable surface. Verify that the clutch is correctly aligned using a clutch alignment tool.

Position the transmission directly in line with the engine’s bellhousing. Gently slide the transmission towards the engine, making sure it is centered. Avoid forcing the transmission into place to prevent damage. Once aligned, secure the bolts and check for proper engagement. This process is crucial for maintaining the longevity and performance of your vehicle’s drivetrain.

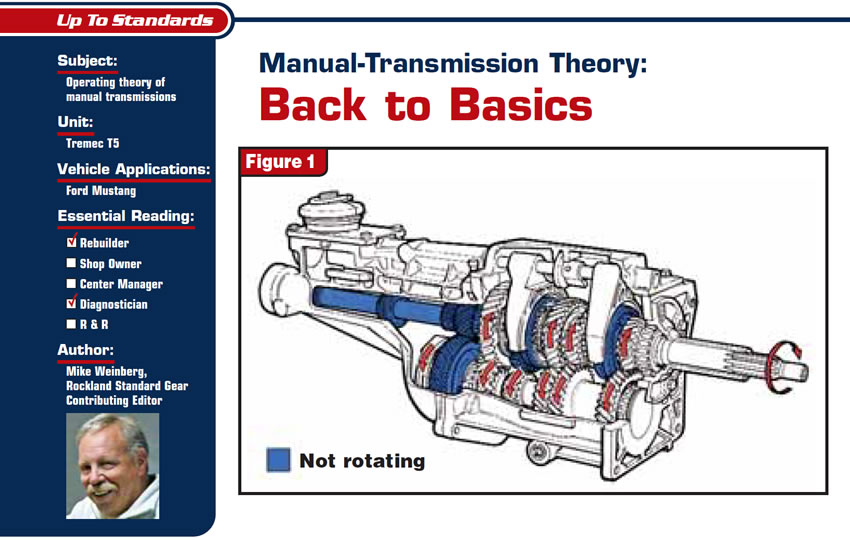

Introduction To Manual Transmission

Aligning a manual transmission with an engine requires precision and careful attention. Properly matching the transmission input shaft to the engine’s flywheel ensures smooth operation. Using the correct tools can make this task easier and prevent potential damage.

Importance Of Precise Alignment

Precise alignment of the manual transmission to the engine is very important. It ensures the smooth operation of the vehicle. Poor alignment can cause damage to both the transmission and the engine. It may also lead to poor performance and increased wear on the components. Always take time to ensure alignment is perfect.

Basics Of Transmission And Engine Connection

The transmission and the engine need to be connected properly. The flywheel on the engine connects to the clutch on the transmission. This connection allows power transfer from the engine to the wheels. It is important to ensure all bolts and parts are secure. Always check for any misalignment or gaps between the parts. Proper connection ensures the vehicle runs smoothly.

Credit: www.transmissiondigest.com

Tools And Materials Needed

Aligning a manual transmission to an engine requires specific tools and materials. Essential items include a transmission jack, alignment dowels, socket set, and a torque wrench. These tools ensure precise alignment and secure installation.

List Of Essential Tools

You need a socket set and a torque wrench. A floor jack will help lift the transmission. A pry bar is useful for adjustments. Clutch alignment tools ensure proper fitting. Transmission jacks provide stability. Wrenches and screwdrivers are necessary for various tasks. Lubricants and grease reduce friction. A clutch fork helps in alignment. A flywheel holder keeps parts in place.

Safety Equipment

Always wear safety glasses to protect your eyes. Gloves keep your hands safe from cuts. Steel-toe boots protect your feet from heavy objects. A face mask is important to avoid inhaling dust. Ear protection is useful in noisy environments. A fire extinguisher should be nearby for emergencies. A first aid kit is essential for minor injuries.

Preparation Steps

Ensure the vehicle is on a flat surface. Use wheel chocks to prevent movement. Disconnect the battery to avoid electrical hazards. Raise the vehicle using a jack and place it on jack stands. Make sure the workspace is well-lit and organized. Gather all necessary tools and safety equipment. Wear protective gloves and goggles for safety.

Drain the transmission fluid into a container. Disconnect the driveshaft and remove the shifter linkage. Support the transmission with a transmission jack. Unbolt the transmission from the engine. Carefully lower the old transmission and move it out of the way. Inspect the clutch and flywheel for wear or damage. Clean the area around the bellhousing and engine block.

Credit: www.truckenterprises.com

Understanding Transmission Alignment

The pilot bearing supports the transmission’s input shaft. It is found in the end of the crankshaft. The bearing reduces friction. It allows the input shaft to rotate smoothly. Without it, the transmission could wear out quickly. The bearing is small but very important. Always check the pilot bearing for damage. Replace it if you see any wear or damage.

Alignment pins help line up the transmission and engine. They ensure everything fits correctly. Misalignment can cause damage. Always use the alignment pins. They make the job easier and safer. Missing pins can cause serious problems. Check for the pins before starting the job. Replace any missing or damaged pins immediately.

Positioning The Clutch And Flywheel

Start by aligning the clutch disc with the flywheel. Use a clutch alignment tool to ensure proper fit. Tighten the bolts in a star pattern. This helps to evenly distribute pressure. Check for any gaps or misalignment. Everything should sit flush and secure.

Place the flywheel against the engine’s crankshaft. Make sure it aligns with the dowel pins. Hand-tighten the bolts to keep it in place. Use a torque wrench to tighten the bolts. Follow the manufacturer’s specifications for torque settings. Double-check all bolts are secure and evenly tightened.

Aligning The Transmission Shaft

An alignment tool is helpful for this task. Insert the tool into the clutch. This aligns the clutch with the flywheel. Make sure the tool fits snugly. A loose tool can cause misalignment. A proper fit ensures a smooth process. Always check the tool’s condition before use.

After using the alignment tool, check the shaft alignment. The shaft should slide in easily. If it doesn’t, recheck your work. A misaligned shaft can damage the engine. Proper alignment ensures smooth operation. Take your time to get it right. Always double-check your work.

Mating The Transmission To The Engine

First, align the transmission input shaft with the clutch disc. Make sure the bell housing is clean and free from debris. Lift the transmission and line it up with the engine. Push the transmission towards the engine gently. Rotate the transmission if it does not slide in smoothly. Use the alignment tool to help with this process.

Insert the transmission bolts and tighten them by hand. Once all bolts are in place, torque them to the manufacturer’s specifications. Reconnect any wiring or hoses that were disconnected. Check for any leaks or loose connections.

If the transmission does not align, check the clutch alignment. Ensure the input shaft is not damaged. Inspect the bell housing for any obstructions. Make sure the engine and transmission are at the same angle. If there is resistance, do not force the transmission. Double-check all connections and consult the service manual if needed.

Final Steps And Testing

Tighten all bolts to the specified torque. Use a torque wrench for accuracy. Start with the bellhousing bolts. Move to the other connections. Ensure each bolt is tight. Check the driveshaft bolts. Do not forget about the crossmember bolts.

Secure all electrical connections. Double-check the clutch linkage. Make sure there are no loose parts. Inspect the area for any missed bolts.

Start the engine. Listen for any unusual sounds. Press the clutch pedal. Shift through all gears. The gears should shift smoothly.

Take the car for a short drive. Test each gear. Make sure the clutch engages properly. Observe for any leaks or odd noises. If everything works well, the job is complete.

Maintenance Tips

Check the alignment often to keep everything running smoothly. Use a flashlight to see better. Make sure the engine and transmission are straight. Look for any wear or damage. Check bolts and screws for tightness. Loose bolts can cause problems. Grease the parts to keep them moving well. Keep a schedule for these checks. It helps to avoid big problems later.

Sometimes, problems can be too hard to fix at home. Call a professional if you hear strange noises. Seek help if you see oil leaks. If the car shakes a lot, get help. Professionals have special tools. They can fix things quickly. Trust them for big repairs.

Credit: www.tremec.com

Frequently Asked Questions

How Does A Manual Transmission Connect To An Engine?

A manual transmission connects to an engine via a clutch and flywheel. The clutch engages and disengages power. The flywheel transfers engine torque to the transmission.

Does A Transmission Have To Match The Engine?

Yes, the transmission must match the engine. Compatibility ensures proper function and prevents mechanical issues. Always check specifications.

How Does Transmission Connect To Engine?

The transmission connects to the engine via the flywheel or flexplate. A clutch or torque converter links them. The transmission then transfers power to the drivetrain, enabling vehicle movement.

What Is The Bearing Between The Engine And Transmission?

The bearing between the engine and transmission is known as the pilot bearing. It supports the transmission input shaft.

Conclusion

Aligning a manual transmission to an engine can seem daunting. Follow the steps carefully for a successful alignment. A properly aligned transmission ensures smooth performance and longevity. Remember to double-check all connections and use the right tools. This guide helps you achieve a seamless and efficient installation process.

Happy driving!