No, you cannot over tighten hydraulic lifters. If you try to over tighten them, they will just spin and not grip the rocker arm.

- The first step is to remove the rocker arms and pushrods

- Next, you will need to loosen the hydraulic lifters

- Once the lifters are loose, you can then remove them from the engine block

- Finally, you will need to reinstall the rocker arms and pushrods

Symptoms of Too Much Lifter Preload

When it comes to engine performance, there are a lot of factors that need to be considered. One of those factors is lifter preload. Too much lifter preload can have negative consequences on your engine, and it’s important to be aware of the symptoms so you can make the necessary adjustments.

One symptom of too much lifter preload is increased valvetrain noise. If you notice that your engine is making more noise than usual, it could be an indication that the lifters are not functioning properly. Additionally, if you see that your valves are not closing completely or if they’re opening and closing at unusual times, that’s another sign that there may be too much preload on the lifters.

Other potential symptoms include loss of power and decreased fuel economy. If you notice any of these issues, it’s important to take action right away in order to avoid further damage to your engine. The good news is that adjusting the preload on the lifters is relatively easy and can often be done with simple tools.

However, if you’re unsure about how to do it or don’t feel comfortable making the adjustment yourself, it’s always best to consult with a professional mechanic who can help get your engine back into top shape.

Credit: davidplanella.org

What Happens When Valves are to Tight?

If valves are too tight, it can cause a number of problems. First, it can lead to leaky valves, which can in turn cause decreased water pressure and even water damage. Additionally, it puts extra strain on the valve itself, which can eventually cause it to break.

Finally, it can make it difficult for the valve to open and close properly, which can impede the flow of water or gas through the piping system.

Are Hydraulic Lifters Self Adjusting?

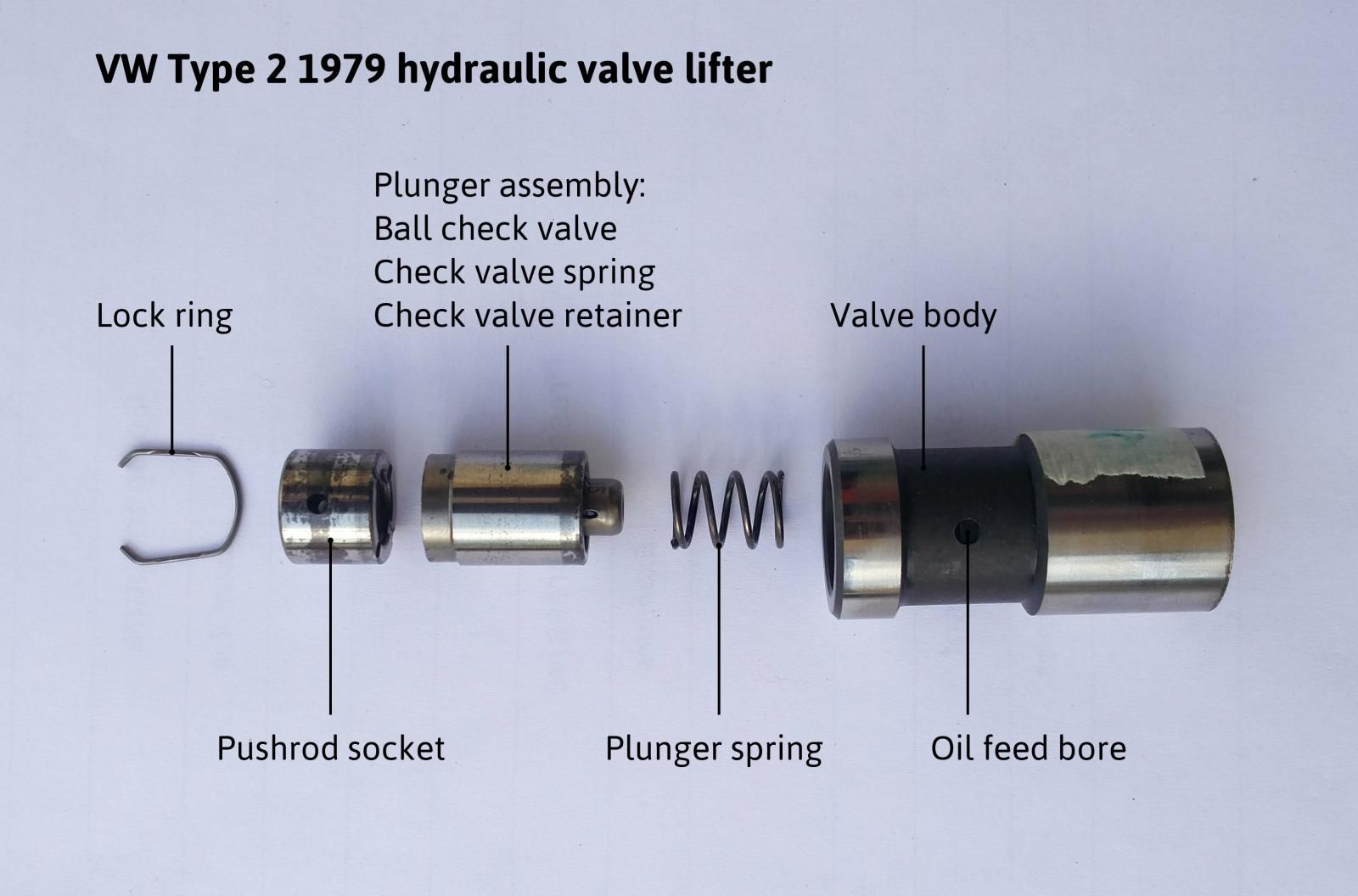

Hydraulic lifters are self-adjusting devices that are used to maintain proper valve clearance in an internal combustion engine. The hydraulic lifter consists of a piston that is located inside a cylinder, and a check ball that is located in a chamber at the bottom of the cylinder. The check ball is held in place by a spring, and when the piston is pushed down, the check ball opens and allows oil to flow into the cylinder.

This oil pressure forces the piston back up, and as it does so, it pushes on the pushrod, which opens the valves. When the engine is turned off, the oil pressure drops and the check ball closes, preventing oil from flowing back into the cylinder.

What’S the Best Way to Adjust Hydraulic Lifters?

If your car’s engine has noisy valves, it may be time to adjust the hydraulic lifters. Hydraulic lifters are used in many cars and trucks to help reduce valvetrain noise. They work by using oil pressure to fill a small chamber in the lifter, which then pushes against a plunger to take up any clearance in the valvetrain.

Adjusting hydraulic lifters is not a difficult task, but it does require some patience and attention to detail. Here are some tips on how to adjust hydraulic lifters:

1) Park your vehicle on a level surface and set the emergency brake.

Locate the rocker arms for the valves you wish to adjust. On most engines, the intake valves will be located on the left side of the engine and the exhaust valves will be located on the right side.

2) Remove the valve cover so that you can access the pushrods.

Use a socket wrench to loosen and remove each pushrod one at a time. Be careful not disturb or damage any other parts as you remove them.

3) With all ofthe pushrods removed, locatethe adjusting screws for each hydraulic lifter.

The adjusting screw is usually located nearthe top ofthe lifter body and is pointing upward when installed correctly .Using a screwdriver or Allen wrench, turn each adjusting screw 1/4 turn clockwise until it stops turning smoothly .Do not force it or over-tighten .

Replace each pushrod making sure that they are positioned correctly before moving onto another valve . If one pushrod is out of position ,it could cause serious engine damage .

How Tight Should Rocker Arms Be?

Rocker arms are an important part of a car’s engine, and they need to be tight in order to function properly. The rocker arm needs to be able to move up and down so that the valves can open and close, and if the rocker arm is too loose, it will not be able to do this properly. If the rocker arm is too tight, however, it can cause problems with the engine’s performance.

It is important to find the right balance when adjusting the tension on the rocker arm, and this can vary depending on the make and model of car.

“Don’t over tighten” rocker or valve lash adjustment on freshly built motor

Conclusion

If you over tighten hydraulic lifters, it can cause damage to the engine. The hydraulic lifters are responsible for lifting the valves in the engine so that they can open and close properly. If they are not working correctly, it can cause a loss of power and efficiency in the engine.