A solenoid valve is a type of valve that uses an electric current to control the flow of liquid or gas. If your solenoid valve becomes stuck, it could prevent water from flowing properly and cause damage to other components in your plumbing system. To fix a stuck solenoid valve, first turn off the electricity powering the unit so that you can safely work on it.

Then use compressed air to blow out any dirt or debris that may have become lodged inside the valve. Next, check for any blockages in the pipes connected to the solenoid and clear them if necessary. Finally, apply lubricant oil such as WD-40 along the moving parts of the valve before running some test cycles with power turned back on to ensure proper operation.

- Step 1: Identify the Stuck Valve

- The first step to fixing a stuck solenoid valve is to identify which valve is stuck

- This can usually be done by listening for a clicking sound when the valves are activated or checking for resistance on the valve stem

- Step 2: Check Power Supply and Connections

- Once you have identified which solenoid valve is stuck, check its power supply to make sure it has electricity running through it and that all of its connections are secure

- Step 3: Clean Out Debris Around Solenoid Valve

- If there is debris such as dirt or rust around the solenoid valve, use compressed air or a brush to clean it out before attempting any repairs

- Step 4: Remove Cover from Solenoid Valve

- To access the internals of the solenoid valve, remove its cover using an adjustable wrench if necessary, depending on how tight it may be screwed in place

- Step 5 : Manipulate Internals of Solenoid Valve

- With the cover off, carefully manipulate any internal parts that could be causing friction and preventing movement like diaphragms or springs until they move freely again; this should fix your stuck solenoid valve issue without needing further repairs!

Credit: gesrepair.com

What Causes a Solenoid to Get Stuck?

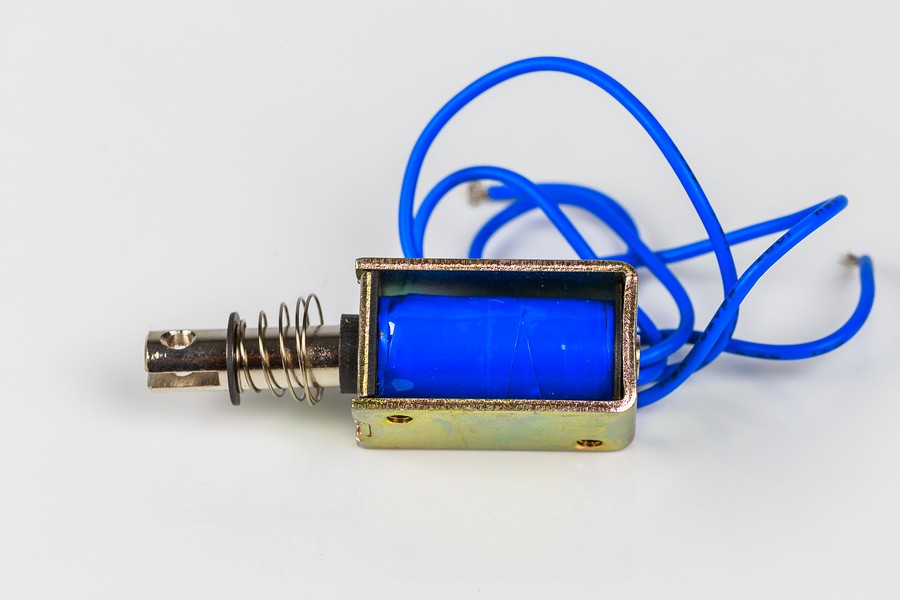

A solenoid is an electromechanical device which converts electrical energy into mechanical energy. It consists of a coil, usually made of copper wire, and a plunger that slides in and out when the current is applied to the coil. The main cause of a solenoid getting stuck is due to dirt or contamination build up inside the plunger and/or around its exterior surface.

This build-up prevents proper movement within the chamber, resulting in either no motion at all or limited motion. Furthermore, corrosion can also worsen this issue as it causes further friction between components leading to even more limitation in movement. Other potential causes include improper installation or incorrect wiring which can lead to misalignment of parts or damage over time.

Finally, insufficient voltage supply could be an underlying problem as well if there isn’t enough power being supplied for proper operation—in other words not enough current running through your system for smooth operation from start to finish!

How Do You Know If Your Solenoid is Stuck?

If you have a solenoid that is stuck, it can be difficult to ascertain the exact cause of the problem. In order to diagnose if your solenoid is stuck, there are several signs and symptoms you should look out for. One sign is an unusually loud humming noise coming from the solenoid or surrounding area when attempting to operate it.

Another sign could be a lack of movement in the output shaft or linkages connected to it despite providing power. If these symptoms persist, further investigation may be needed such as checking for voltage drops across connections, measuring resistance between terminals and/or determining continuity of wires throughout its circuit path. Additionally, visual inspection can provide clues on whether specific components are cracked or damaged which may indicate why the solenoid has become stuck in place.

Once any potential problems with the wiring or components have been identified and rectified then your issue should hopefully resolved allowing for normal operation once again!

How Do You Reset a Solenoid Valve?

Resetting a solenoid valve is an important process that should be done correctly in order to ensure the optimal performance of your system. A solenoid valve is basically an electro-mechanical device that controls the flow of liquid or gas by opening and closing its internal valves with electromagnets. Resetting it requires you to cut off all power, remove any debris from around the unit, check for corrosion on electrical connections, and clean off any dirt or dust inside.

Once everything has been checked and cleaned, then you can reconnect the power source to initiate resetting procedures. This involves setting up a timer so that when it reaches zero voltage across each terminal contact point, this will cause a current surge which will activate the reset switch inside the unit. After doing this successfully, you can turn on your system again and it should be working properly once more.

How Do You Manually Open a Solenoid Valve?

Manually opening a solenoid valve is relatively easy and can be done with the right tools. First, you will need to disconnect the power supply from the solenoid valve. This is important for safety reasons as it prevents any electric shock should an accident occur.

Then, using a screwdriver or spanner, unscrew the top of the solenoid valve body and remove it carefully. Inside you’ll find two screws that hold down a plastic lid which covers the internal mechanism of your valve; these must both be removed in order to access the inner workings of your solenoid valve. Once all this has been completed, locate and rotate the small metal lever at the bottom of your valve until it clicks into place – this action will manually open your solenoid valve allowing water or air to flow through it freely.

Finally replace all components back together again, re-attach power supply if required and test to ensure that everything works correctly before use!

How To Fix A Stuck Solenoid Valve

Stuck Solenoid Symptoms

A stuck solenoid can cause a variety of symptoms, including an inability to start the car, engine stalling or backfiring when starting, and a clicking sound from under the hood. Additionally, you may notice that your headlights are dimming or flickering when trying to start the car. If any of these symptoms occur, it could be a sign that your solenoid is stuck and needs to be serviced.

Conclusion

Fixing a stuck solenoid valve can be a great way to save time and money. With the right tools and technique, it is possible to repair and maintain your valves without needing to replace them. Understanding how the valve works, what could cause it to become stuck, and knowing how to fix the problem are all important steps in ensuring that your system runs smoothly for many years.

Knowing when professional help is needed will also help you avoid any potential disasters or costly repairs.